For consumers worried about the risks associated with using lithium-ion batteries — which are used in everything from phones to laptops to electric vehicles — Michigan State University has discovered that a natural material found in wood can improve battery safety while also improving the battery’s life.

Chengcheng Fang, assistant professor in the College of Engineering, and Mojgan Nejad, an associate professor in the College of Agriculture and Natural Resources, collaborated to engineer lignin, a natural ingredient of wood that provides support and rigidity, into a thin film separator that can be used inside lithium-ion batteries to prevent short circuits that can cause a fire.

“We wanted to build a better battery,” said Fang. “But we also wanted it to be safe, efficient and sustainable.”

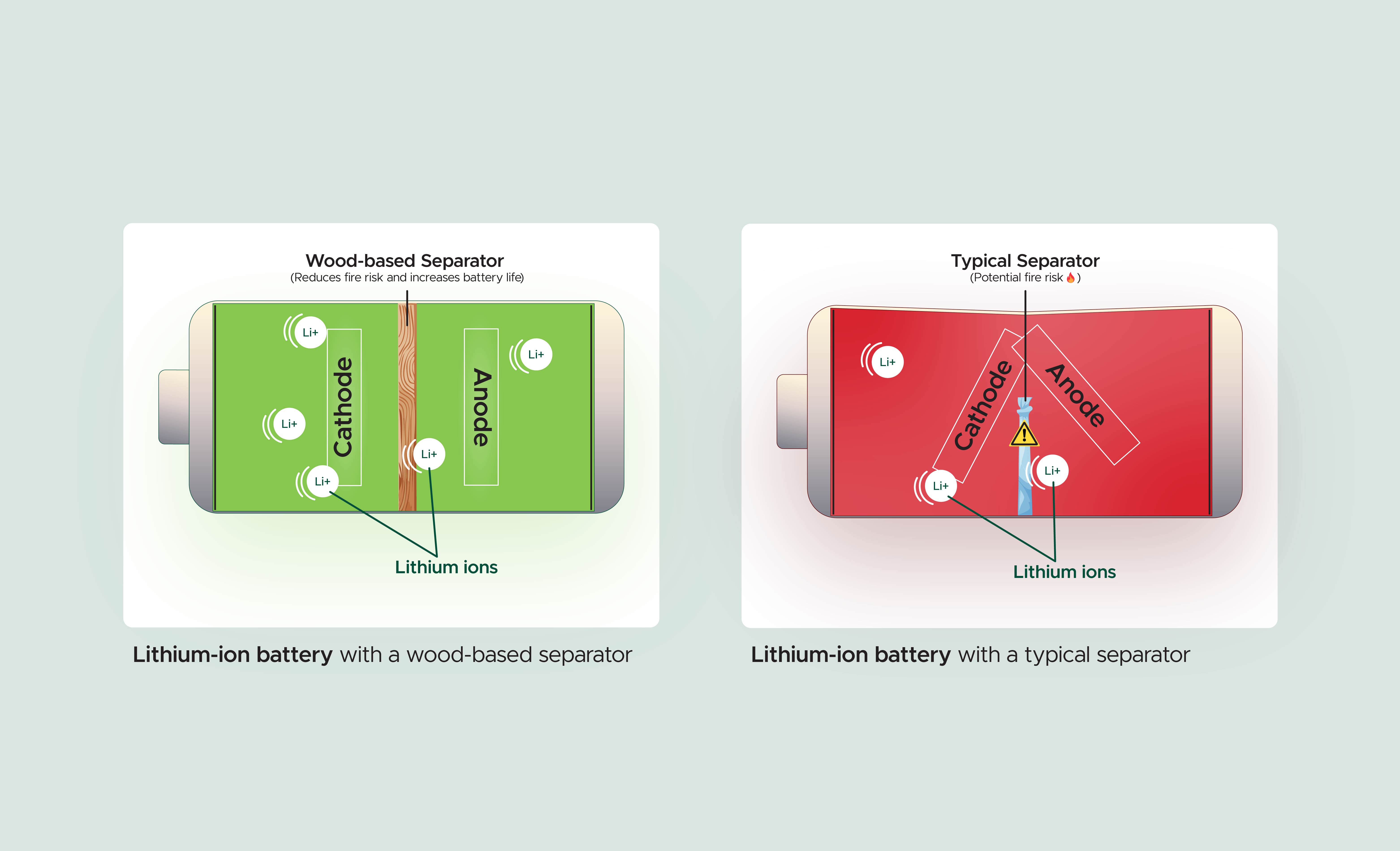

Inside a battery, the positively charged cathode and negatively charged anode electrodes help the flow of electricity. To keep these electrodes apart, a commercial separator is typically made from polyethylene and polypropylene plastic materials, which can shrink at temperatures near 100 degrees Celsius. Without the protection of the separator, the cathode and anode sides of the battery have the potential to touch, causing an accidental short circuit and possible fire or explosion.

In contrast, the lignin-based separators developed remained stable and didn’t become smaller in size up to temperatures of 300 degrees Celsius.

Fang and her team tested varying thicknesses of lignin and found that films measuring 25 micrometers, which is thinner than one quarter of a human hair, were the most effective at keeping the inside of the battery stable and keeping the anode and cathode from connecting.

Using the lignin film inside the battery had another benefit: the increased stability inside the battery also resulted in an improved cycle life, or how many times the battery can be charged and used.

“We were surprised to see that the lignin film also improved the battery’s cycle life,” said Fang. “We increased the battery’s cycle life by 60%.”

A third advantage of this research is an environmentally friendly one. The team was able to manufacture the lignin separators using a low-cost dry processing method. This meant that the team was able to produce large quantities of the lignin film, on demand, while avoiding the use of harmful solvents commonly used in traditional separator manufacturing, which can be harmful to the environment. In this case, the researchers were able to use lignin and other materials that provided a 100% raw material conversion to create a film without creating any waste or pollution.

“Lignin, particularly lignosulfonate, is naturally abundant and it doesn’t need any further treatment to function in batteries,” said Fang. “This work demonstrates a new design pathway to improve both the safety and manufacturability of battery materials.”

This research was published in Advanced Materials, and the technology is patent pending through the MSU Innovation Center.