A team of Michigan State University researchers believes in a future when homes and other buildings can be constructed using low-cost, sustainable materials that also can repair themselves and capture carbon dioxide from the atmosphere.

The National Science Foundation shares that belief, having awarded those Michigan State researchers and colleagues at Purdue University $2 million to help deliver that future sooner than later.

“To reduce greenhouse gas emissions and fight climate change, there is strong demand in sustainable materials,” said Jinxing Li, who leads the project.

Li is an assistant professor in the College of Engineering and the Institute for Quantitative Health Science and Engineering, or IQ, at MSU.

“That’s really forcing us to think about how we make everything,” Li said. “We need to find new ways to make our buildings, as both the current construction materials and the construction process are big contributors of our carbon footprint.”

The team’s idea is a blend of straightforward thinking with innovative materials science and emerging construction technologies. That idea is centered on creating 3D-printed construction materials in which microbes can thrive to naturally remove greenhouse gases and repair damage.

“It’s a simple idea: basically, ‘let’s engineer microbes to build better materials for us,’” Li said. “That’s like 10 words but, with all the science and reasoning that goes into it, our research plan was closer to 15 pages.”

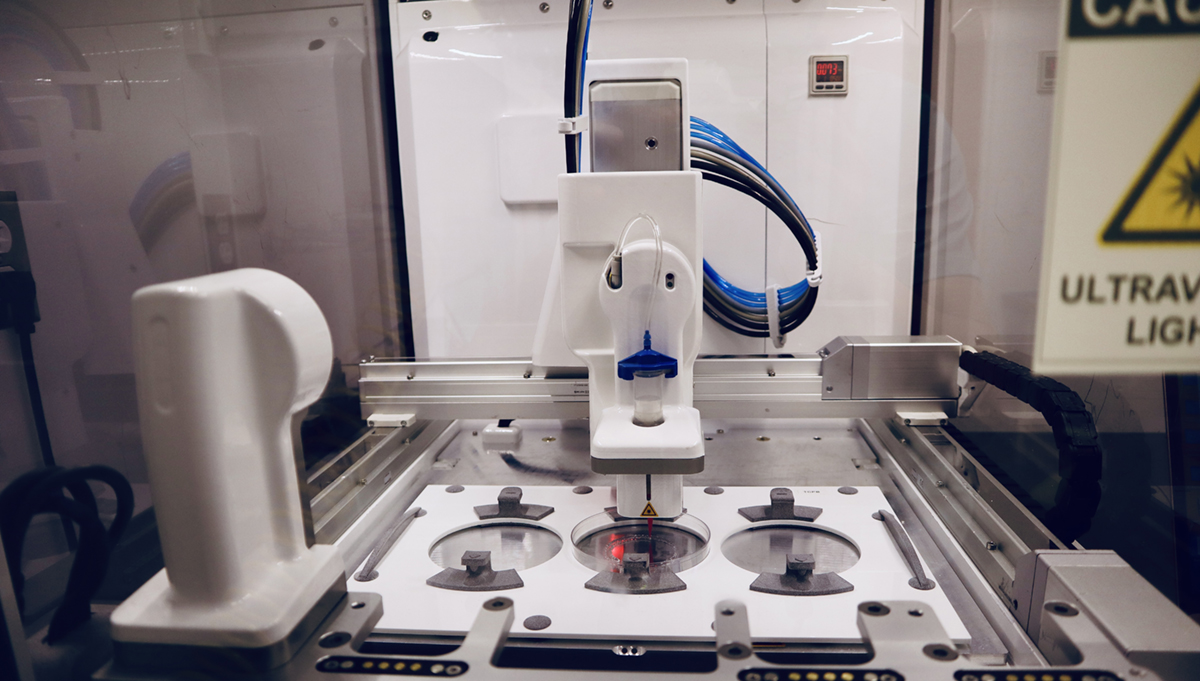

To build with these microbe-infused materials, the team will be capitalizing on the potential of additive manufacturing or 3D printing. Li is also the faculty lead of IQ’s 3D printing core facility.

Currently, 3D printing is best known for the commercial benchtop machines that can create custom parts and prototypes by building them up one layer at a time using polymer resin or “ink.”

But 3D printing is also being put to work in construction, using industrial robots and brawnier inks, such as concrete.

The new MSU-led project focuses on creating new inks, derived from sustainable biomass sources, including agricultural waste — the parts of plants that farmers can’t sell.

“Around MSU and in the Great Lakes region, we have rich biomass resources,” Li said. “We believe this can be scalable locally and nationally.”

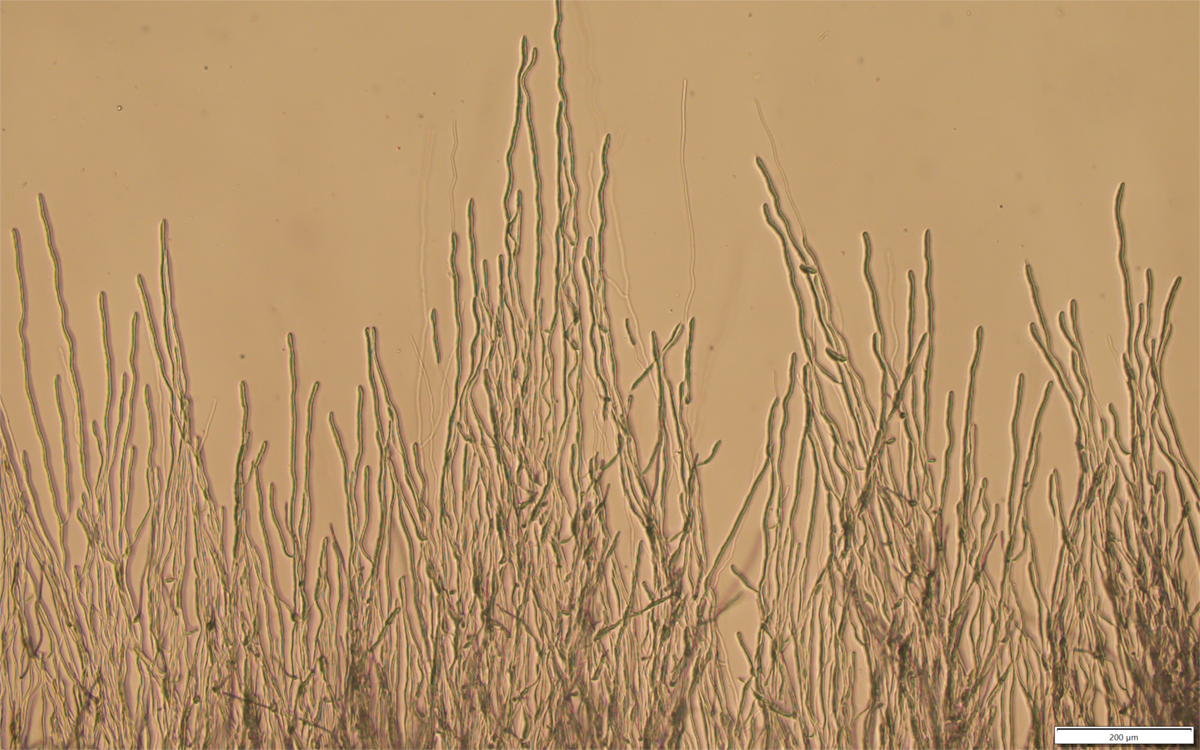

That biomass contains compounds called lignin and cellulose that can be incorporated into inks to provide structural fortitude. The next step is adding microscopic fungi and bacteria to the ink that can not only survive, but also thrive to provide additional benefits.

With the right blend of biology and chemistry, the microbes will make polymers and minerals that can fortify the cellulose and lignin matrix at a microscopic scale. As the materials start to show signs of aging and stress — such as microcracks — the microbes can also work to heal these damage sites. What’s more, the microbes collect carbon from the atmosphere to do this.

Building confidence and opportunities

Innovating carbon-negative materials that can compete with conventional building products is an enterprising project — and one that nearly didn’t materialize.

“This is definitely a high-risk, high-reward project. There was a lot of uncertainty initially due to the complexity of the project and its cross-disciplinary nature,” Li said. “But when you find the right team, there’s a resonance. You start building ambition and rationale together — and creating opportunities.”

That ambition and rationale was rewarded by the NSF’s Emerging Frontiers in Research and Innovation program that supports “discovery at the frontiers of engineering research and education.”